Where to Buy Affordable Aluminum Siding for Your Home is a question many homeowners ask. Finding the right balance between cost and quality can be challenging, but understanding the market and your options makes the process significantly easier. This guide explores various avenues for purchasing affordable aluminum siding, considering factors like material quality, installation costs, and financing options to help you make an informed decision.

From identifying reputable manufacturers and online retailers to understanding the nuances of installation and maintenance, we’ll cover essential aspects to ensure you achieve the best possible outcome for your home improvement project. We’ll also delve into the importance of warranties, environmental considerations, and ways to avoid hidden costs, equipping you with the knowledge to navigate the process confidently.

Defining “Affordable”

Determining the affordability of aluminum siding hinges on a variety of factors, making it difficult to assign a single price point that applies universally. The cost varies significantly based on location, project size, and the quality of materials and labor involved. Understanding these variables is key to making an informed decision.

Affordability in the context of aluminum siding typically refers to a price range that represents good value for the investment, considering the product’s longevity and maintenance requirements. While the initial outlay might be higher than some alternatives, the long-term cost-effectiveness should be a primary consideration.

Price Ranges for Affordable Aluminum Siding

The price of aluminum siding typically ranges from $3 to $12 per square foot, including both materials and installation. This wide range reflects differences in material quality (thickness, finish, color), labor costs (regional variations and contractor experience), and the complexity of the installation (e.g., intricate trim work, multiple architectural features). In regions with higher labor costs, such as major metropolitan areas on the East and West Coasts, the higher end of this range is more common. More rural areas might see prices closer to the lower end. A homeowner in a rural area of the Midwest might find $4-$6 per square foot to be a reasonable price, while someone in New York City might consider $8-$12 per square foot affordable, recognizing the increased cost of labor.

Factors Influencing Perceived Affordability

Several factors beyond the base price per square foot significantly impact the perceived affordability of aluminum siding.

Material quality plays a crucial role. Thicker aluminum sheets are more durable and resistant to damage, justifying a higher initial cost. Premium finishes, such as those with enhanced fade resistance or textured surfaces, also increase the price. However, these premium materials often translate to lower long-term maintenance costs and increased lifespan, making the investment worthwhile for many homeowners.

Installation costs constitute a substantial portion of the overall expense. The complexity of the project, including the size of the house, the number of architectural details, and the need for specialized labor (e.g., for difficult-to-reach areas), directly affects labor costs. Choosing a reputable and experienced installer is crucial, even if it means a slightly higher upfront cost, as it minimizes the risk of costly mistakes or future repairs.

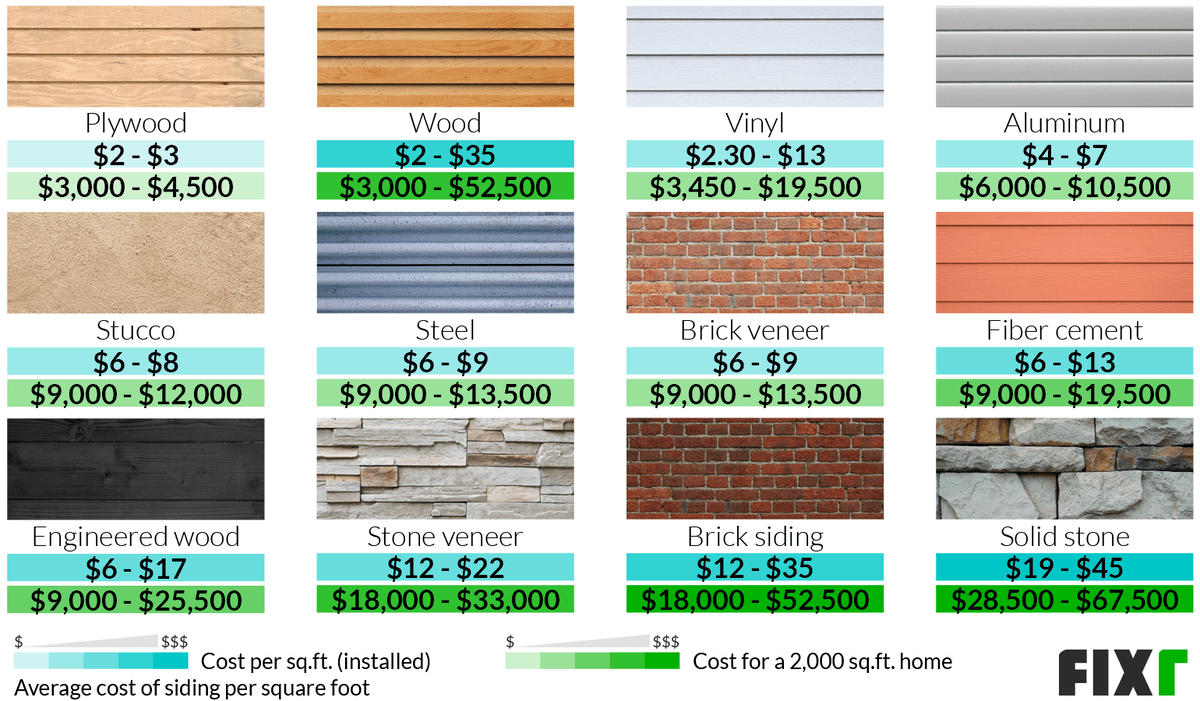

Price Comparison of Siding Materials

The following table compares the approximate price ranges for aluminum siding with other common siding materials. These figures are estimates and can vary significantly based on location, quality, and installation costs.

| Siding Material | Price Range Per Square Foot (USD) | Pros | Cons |

|---|---|---|---|

| Aluminum | $3 – $12 | Durable, low maintenance, long lifespan, fire-resistant | Higher initial cost compared to vinyl, can dent |

| Vinyl | $1 – $6 | Affordable, easy to install, low maintenance | Less durable than aluminum, can fade or crack |

| Wood | $4 – $20+ | Aesthetically pleasing, natural look | High maintenance, susceptible to rot and insect damage, expensive |

| Fiber Cement | $6 – $15 | Durable, fire-resistant, low maintenance | More expensive than vinyl, requires professional installation |

Sourcing Aluminum Siding

Finding the right aluminum siding for your home involves understanding where to source it and comparing options to ensure you get the best value for your budget. This section will explore various avenues for purchasing aluminum siding, highlighting the advantages and disadvantages of each. Careful consideration of these options will help you make an informed decision.

Major Aluminum Siding Manufacturers and Distribution Channels

Several major manufacturers produce aluminum siding, each with its own distribution network. These manufacturers often sell their products through a combination of wholesale distributors, specialized siding contractors, and, in some cases, directly to consumers. Understanding these channels is crucial for securing competitive pricing and reliable installation services.

- Alcoa: A leading producer of aluminum products, Alcoa’s siding is often available through building material suppliers and contractors specializing in exterior renovations. Their distribution often relies on a network of established wholesalers and dealers.

- CertainTeed: Known for a wide range of building materials, CertainTeed offers aluminum siding distributed through a similar network to Alcoa, including home improvement retailers and contractors.

- Mastic: Mastic, a prominent player in the exterior cladding market, typically distributes its aluminum siding through a network of independent dealers and contractors, alongside some larger home improvement chains.

Online Retailers Specializing in Aluminum Siding Sales and Pricing Strategies

The internet provides a convenient platform for comparing prices and finding deals on aluminum siding. However, it’s important to be aware of the different pricing strategies employed by online retailers. Some may offer competitive pricing on bulk orders, while others may focus on offering a wider selection of styles and colors, potentially at a higher price point. Always compare total costs, including shipping and handling fees.

- Many online retailers operate as marketplaces, listing products from various manufacturers and suppliers. Pricing can vary significantly depending on the seller and the specific product specifications.

- Some online retailers specialize in home improvement supplies and offer competitive pricing by leveraging bulk purchasing power. They may offer discounts for larger orders or bundle deals that include installation materials.

- Direct-to-consumer manufacturers may offer online sales, often bypassing the traditional distribution network. This can potentially result in lower prices but might require more direct involvement in the purchasing and shipping process.

Big-Box Stores versus Specialized Siding Contractors

Purchasing aluminum siding from big-box stores versus specialized siding contractors presents distinct advantages and disadvantages. Big-box stores offer convenience and potentially competitive pricing on standard products, but may lack the specialized knowledge and service provided by experienced siding contractors.

- Big-box stores typically offer a limited selection of aluminum siding options and may not provide comprehensive installation services. However, they are generally convenient for smaller projects and readily accessible.

- Specialized siding contractors often offer a wider selection of siding options, expert installation services, and potentially better warranties. They can also provide valuable advice on choosing the right siding for your home and climate. However, their services typically come at a higher cost.

Evaluating Material Quality

Choosing high-quality aluminum siding is crucial for ensuring the longevity and aesthetic appeal of your home’s exterior. The initial cost savings of lower-quality materials can quickly be offset by premature deterioration, requiring costly repairs or replacements. Understanding the key characteristics of durable aluminum siding will help you make an informed decision.

Aluminum siding thickness, coating type, and manufacturer warranty are key indicators of quality. Thicker siding generally offers greater resistance to dents and damage, while a high-quality coating protects against fading, chipping, and corrosion. A comprehensive warranty demonstrates the manufacturer’s confidence in their product.

Aluminum Siding Thickness and Gauge

Aluminum siding is measured by its gauge, a number inversely proportional to thickness. Lower gauge numbers indicate thicker siding. For example, a .032-inch thick siding (gauge 26) is considered more durable than a .024-inch thick siding (gauge 28). Thicker aluminum siding better withstands impacts from hail, debris, and accidental bumps, contributing to a longer lifespan. This added durability translates to less frequent repairs and replacements, ultimately saving you money in the long run. While thicker siding generally costs more upfront, the investment pays off in increased longevity and reduced maintenance.

Aluminum Siding Coatings and Finishes

The coating applied to aluminum siding significantly influences its resistance to weathering and fading. Two common types are painted and powder-coated finishes. Painted finishes, while generally less expensive, are often less durable than powder-coated finishes. Powder-coating involves applying a dry powder coating and then curing it at high temperatures, resulting in a thicker, more resilient finish that better resists chipping, peeling, and fading. Powder-coated siding often comes with longer warranties reflecting its superior performance. The choice between painted and powder-coated siding depends on budget and desired longevity; powder-coating offers superior protection and longevity but commands a higher initial cost.

Warranty Information and Manufacturer Reputation

A comprehensive warranty is a strong indicator of a manufacturer’s confidence in their product. Look for warranties that cover defects in materials and workmanship for an extended period, typically 20-30 years or longer. A reputable manufacturer will stand behind their product and offer prompt resolution of any issues. Checking online reviews and ratings from previous customers can also help assess the manufacturer’s reliability and customer service. Understanding the specifics of the warranty, including what is and is not covered, is crucial before making a purchase.

Questions to Ask Manufacturers or Suppliers

Before committing to a purchase, it is essential to gather all necessary information regarding material quality and warranties. The following points should be clarified:

- What is the gauge (thickness) of the aluminum siding?

- What type of coating is used (painted, powder-coated, etc.) and what is its thickness?

- What is the warranty period and what specific defects are covered?

- What is the manufacturer’s reputation and history in the industry?

- Are there any independent certifications or testing results verifying the siding’s quality and durability?

- What are the available color options and their fade resistance ratings?

Installation Costs and Considerations

Installing aluminum siding involves significant costs, encompassing both materials and labor. Understanding these expenses is crucial for budgeting and making informed decisions about your home improvement project. Accurate cost estimation depends on several key factors, allowing for a realistic assessment of the overall investment.

The total cost of aluminum siding installation is typically a combination of material costs and labor charges. Material costs vary depending on the type of siding chosen (thickness, color, style), the amount needed (square footage of your home), and the supplier. Labor costs are heavily influenced by factors such as the complexity of the installation (e.g., intricate trim work, multiple gables), the size of your home, and prevailing regional labor rates. In many cases, contractors provide a comprehensive quote encompassing both materials and labor.

Typical Installation Cost Breakdown

A detailed breakdown of installation costs is difficult to provide without specifics about your home and location. However, we can offer a general range based on national averages. Keep in mind that these are estimates and actual costs may vary significantly. Always obtain multiple quotes from reputable contractors for accurate pricing in your area.

For a typical single-family home, the cost of aluminum siding installation can range from $6,000 to $15,000 or more. This includes both materials and labor. The lower end of the range often applies to smaller homes with simpler designs and straightforward installations, while the higher end reflects larger homes, complex architectural features, and potentially higher labor rates in certain regions.

Factors Influencing Installation Costs

Several factors significantly impact the final cost of your aluminum siding installation. Understanding these variables allows for better budgeting and realistic expectations.

- Home Size: Larger homes naturally require more materials and more labor hours, leading to higher overall costs.

- Home Complexity: Homes with intricate architectural details, such as dormers, multiple gables, or complex trim work, increase labor time and thus the cost. These details require more precision and careful installation.

- Regional Labor Rates: Labor costs vary significantly across geographical locations. Areas with higher costs of living generally have higher labor rates for contractors.

- Material Choice: The type of aluminum siding selected impacts the material cost. Higher-quality siding, featuring thicker gauge aluminum or specialized finishes, will be more expensive.

- Existing Siding Removal: If existing siding needs removal before installation, this adds to both labor and disposal costs.

DIY Installation versus Hiring a Professional

The decision to install aluminum siding yourself or hire a professional contractor involves weighing the potential benefits and risks of each approach.

| Factor | DIY Installation | Professional Installation |

|---|---|---|

| Cost | Potentially lower initial cost (materials only) | Higher initial cost (materials and labor) |

| Time | Significantly longer project duration | Faster project completion |

| Skill Level | Requires significant experience and skill | Expertise and experience guaranteed |

| Warranty | Limited or no warranty on installation | Warranty typically provided on both materials and labor |

| Risk of Damage | Higher risk of damage to the home or improper installation | Lower risk of damage or improper installation |

While DIY installation might seem cost-effective initially, the potential for errors, damage, and increased project time can ultimately negate any savings. Professional contractors possess the expertise, tools, and insurance to ensure a proper and safe installation, offering peace of mind and a warranty to protect your investment.

Financing Options

Securing funding for your aluminum siding project can significantly impact your budget and timeline. Understanding the various financing options available allows you to make informed decisions based on your financial situation and the project’s scope. This section will explore several common methods, highlighting their advantages and disadvantages.

Several financing avenues exist for home improvement projects, each with its own set of benefits and drawbacks. Choosing the right option depends heavily on factors such as your credit score, the project’s cost, and your repayment comfort level. Careful consideration of these factors will lead to a more financially sound decision.

Home Improvement Loans

Home improvement loans are specifically designed for projects like siding replacement. These loans offer fixed interest rates, predictable monthly payments, and longer repayment periods than credit cards. However, they typically require a credit check and may involve closing costs. For example, a homeowner might secure a 5-year loan with a 7% interest rate to cover a $10,000 siding project. The monthly payments would be calculated based on the loan amount, interest rate, and loan term. This predictability allows for better budgeting.

Credit Cards

Credit cards offer immediate access to funds, making them convenient for smaller projects. However, high interest rates and potential for accumulating debt are significant drawbacks. Using a credit card for a large home improvement project could lead to substantial interest charges over time if not paid off quickly. For instance, using a credit card with a 18% APR to finance a $5,000 project could result in significantly higher total costs compared to a home improvement loan.

Home Equity Loans or Lines of Credit (HELOCs)

Home equity loans and HELOCs use your home’s equity as collateral. HELOCs offer flexibility, allowing you to borrow funds as needed up to a pre-approved limit. Home equity loans provide a lump-sum payment. Both options typically offer lower interest rates than credit cards but carry the risk of foreclosure if payments are not made. For larger projects, a HELOC might be advantageous, allowing for staged payments as the project progresses. However, it’s crucial to understand the terms and conditions, including potential interest rate fluctuations with a HELOC.

Comparison of Financing Options

The following table compares common financing options for home improvement projects. Remember that interest rates and terms can vary based on your creditworthiness and the lender.

| Financing Option | Typical Interest Rate Range | Typical Repayment Term | Advantages |

|---|---|---|---|

| Home Improvement Loan | 6% – 12% | 1-7 years | Fixed interest rate, predictable payments, longer repayment period |

| Credit Card | 15% – 25% | Varies, often revolving | Immediate access to funds, convenience |

| Home Equity Loan | 5% – 10% | 5-15 years | Lower interest rates than credit cards, lump sum payment |

| HELOC | Variable, typically lower than credit cards | Draw period and repayment period vary | Flexibility, access to funds as needed |

Warranty and Guarantees

Protecting your investment in new aluminum siding requires careful consideration of the warranty offered by the manufacturer and installer. A comprehensive warranty provides peace of mind and safeguards against potential defects or issues that may arise over time. Understanding the specifics of different warranty types is crucial for making an informed purchasing decision.

A thorough review of warranty information is paramount before committing to a purchase. Warranties vary significantly between manufacturers, impacting the level of protection you receive. Some may only cover material defects, while others might extend coverage to include workmanship or even labor costs associated with repairs. Choosing a product with a robust warranty can significantly reduce the risk of unforeseen expenses down the line.

Warranty Types Offered by Manufacturers

Manufacturers typically offer several types of warranties for their aluminum siding products. These warranties often address different aspects of the product and its installation. Common types include material defect warranties, which cover flaws in the manufacturing process, and workmanship warranties, which cover issues arising from improper installation. Some manufacturers offer combined warranties encompassing both material and workmanship, providing more comprehensive coverage. Additionally, some may offer extended warranties for an additional cost, providing longer-term protection. For example, one manufacturer might offer a 30-year warranty against material defects, while another might offer a 20-year warranty that covers both material defects and workmanship. A third might offer a 25-year limited warranty covering material defects, with an option to purchase a 10-year extended warranty covering labor. These differences highlight the importance of carefully comparing warranty terms.

Key Aspects to Consider When Evaluating an Aluminum Siding Warranty

Before finalizing your purchase, carefully examine the warranty’s fine print. A checklist of essential considerations includes:

- Warranty Period: Note the duration of coverage for material defects and workmanship. Longer warranty periods generally indicate higher confidence in the product’s quality and durability.

- Coverage Details: Understand precisely what is covered under the warranty. Does it include only material defects, or does it also encompass labor costs for repairs or replacements? Are there specific exclusions, such as damage caused by extreme weather events?

- Transferability: Determine if the warranty is transferable to a future homeowner should you sell your property. Transferable warranties add significant value to your home.

- Claim Process: Review the procedure for filing a warranty claim. Is it straightforward, or are there complex requirements or lengthy processing times?

- Manufacturer Reputation: Research the manufacturer’s reputation and track record for honoring warranties. Online reviews and customer testimonials can offer valuable insights.

- Written Documentation: Ensure you receive a clear and concise written warranty document. This document should clearly outline all terms and conditions of the warranty.

Local Suppliers and Contractors

Finding the right local supplier and contractor is crucial for a successful aluminum siding project. Choosing reputable professionals ensures quality materials, proper installation, and peace of mind. This section will guide you through the process of identifying and vetting potential partners for your home improvement project.

Locating reputable local suppliers and contractors involves a multi-pronged approach. Online searches, referrals from trusted sources, and direct inquiries within your community are all effective strategies. Thorough vetting is paramount to avoid potential pitfalls and ensure a positive experience.

Finding Reputable Local Suppliers and Contractors

Several methods exist for finding qualified professionals. Online directories, such as those provided by the Better Business Bureau (BBB) and Angie’s List, offer ratings and reviews from past clients. Local home improvement stores often have relationships with reliable contractors and can provide recommendations. Networking within your community—asking friends, neighbors, and family for recommendations—can also yield valuable leads. Finally, checking with your local building permits office may provide a list of licensed contractors operating in your area. It’s advisable to contact several suppliers and contractors to compare prices and services.

Vetting Potential Contractors

Before committing to a contractor, a thorough vetting process is essential. This involves verifying their licensing and insurance, checking online reviews, and requesting references. Confirm that the contractor holds the necessary licenses to operate legally in your area. Verify they carry adequate liability and workers’ compensation insurance to protect you from potential financial liabilities in case of accidents or damages. Examine online reviews on platforms like Yelp, Google My Business, and the BBB to gauge customer satisfaction and identify any recurring issues. Request references from previous clients to directly inquire about their experiences with the contractor’s work quality, professionalism, and adherence to deadlines.

Negotiating Prices and Securing Favorable Terms

Negotiating prices and securing favorable terms requires preparation and clear communication. Obtain multiple quotes from different contractors to compare pricing and services. Clearly outline your project requirements, including the scope of work, materials, and desired timeline. Don’t hesitate to negotiate based on the quotes received, highlighting competitive pricing from other contractors. Clarify payment terms, including the down payment amount, payment schedule, and any penalties for late payments. Ensure the contract clearly specifies all aspects of the project, including materials used, warranty provisions, and dispute resolution mechanisms. A well-defined contract protects both you and the contractor, minimizing the potential for misunderstandings or disputes. For larger projects, consider breaking down the project into phases with milestone payments linked to the completion of each phase.

Environmental Impact

Aluminum siding, while offering durability and affordability, carries environmental implications throughout its lifecycle, from manufacturing to disposal. Understanding these impacts allows for informed decision-making, promoting responsible home improvement choices. This section details the environmental considerations associated with aluminum siding, comparing it to alternatives and outlining recycling options.

Aluminum siding production is energy-intensive. The extraction of bauxite ore, the primary aluminum source, requires significant energy consumption and can lead to habitat disruption and water pollution. The smelting process, transforming bauxite into aluminum, also necessitates substantial energy input, often relying on fossil fuels, contributing to greenhouse gas emissions. Furthermore, the manufacturing of siding involves additional energy usage for processes like rolling, coating, and finishing.

Aluminum Siding Manufacturing and Disposal

The environmental impact of aluminum siding manufacturing stems primarily from energy consumption during bauxite mining and aluminum smelting. These processes contribute to greenhouse gas emissions and habitat destruction. Disposal presents another concern, as improper disposal can lead to landfill accumulation and resource depletion. However, the durability of aluminum siding often translates to a longer lifespan compared to some alternatives, potentially offsetting some of the initial environmental costs. The impact can be further reduced by choosing recycled aluminum content in the siding itself.

Comparison with Other Siding Materials

Compared to other common siding materials, aluminum siding presents a mixed environmental profile. Vinyl siding, while often cheaper initially, is derived from petroleum, a non-renewable resource, and releases harmful chemicals during manufacturing and incineration. Wood siding, while renewable, requires extensive logging, potentially impacting forests and biodiversity. The environmental impact of each material depends on factors such as manufacturing processes, transportation distances, and end-of-life management. Life cycle assessments, which consider the entire lifespan of a product, are necessary for comprehensive comparisons. For instance, a life cycle assessment might reveal that while the initial energy input for aluminum is high, its longevity and recyclability can make its overall environmental impact comparable to, or even better than, other options, depending on the specific scenarios and the other materials being compared.

Aluminum Siding Recycling

Aluminum is a highly recyclable material. At the end of its lifespan, aluminum siding can be recycled and reused in the production of new aluminum products, significantly reducing the demand for newly mined bauxite. Many scrap metal recycling centers accept aluminum siding. The recycling process requires significantly less energy than primary aluminum production, minimizing environmental impact. Checking with local recycling facilities to confirm their acceptance of aluminum siding is recommended before undertaking removal and disposal. The high recyclability rate of aluminum makes it a more environmentally sustainable option compared to materials with lower recyclability rates, such as vinyl.

Long-Term Maintenance

Aluminum siding, while durable, requires regular maintenance to preserve its appearance and extend its lifespan. Neglecting maintenance can lead to increased repair costs and a diminished aesthetic appeal. Understanding the typical maintenance needs and potential damage scenarios is crucial for homeowners.

Aluminum siding is relatively low-maintenance compared to other siding materials, but it still needs attention to keep it looking its best and functioning properly. Proper care prevents costly repairs and extends the life of your investment.

Cleaning Aluminum Siding

Regular cleaning is essential for removing dirt, grime, and other debris that can accumulate over time. This prevents staining and helps maintain the siding’s original color and luster. A simple solution of mild detergent and water, applied with a soft brush or sponge, is usually sufficient. Power washing can be used, but should be done cautiously to avoid damaging the siding’s finish. Excessive pressure can strip paint or damage the surface. For stubborn stains, a specialized siding cleaner might be necessary, always following the manufacturer’s instructions. Annual cleaning is recommended, but more frequent cleaning may be necessary depending on environmental factors, such as proximity to trees or heavy pollution.

Repairing Damaged Aluminum Siding

Despite its durability, aluminum siding can be susceptible to damage from impacts, such as hail or flying debris. Minor dents can often be repaired by carefully pushing the dent back into place from the back side of the panel. More significant damage, such as large dents, cracks, or holes, may require panel replacement. The cost of repair will vary depending on the extent of the damage and the labor involved. For example, replacing a single damaged panel might cost between $50 and $150, including the cost of the replacement panel and labor, while more extensive repairs could cost several hundred dollars. It’s advisable to contact a qualified siding contractor for significant repairs to ensure proper installation and prevent further damage.

Maintenance Schedule for Aluminum Siding

A proactive maintenance schedule helps prevent costly repairs and keeps your aluminum siding looking its best.

| Task | Frequency | Notes |

|---|---|---|

| Cleaning (mild detergent and water) | Annually | More frequent cleaning may be needed in areas with heavy pollution or near trees. |

| Inspection for damage | Semi-annually | Check for dents, cracks, loose panels, or other signs of damage. |

| Caulk inspection and repair | Annually | Check caulking around windows and doors for cracks or gaps. Repair as needed. |

| Professional inspection | Every 5-10 years | A professional can identify potential problems early on and recommend necessary repairs. |

Style and Aesthetics

Aluminum siding offers a surprisingly diverse range of aesthetic options, moving beyond the perception of a purely utilitarian material. Careful selection can significantly enhance a home’s curb appeal and complement its architectural style, providing a durable and attractive exterior. The key lies in understanding the available styles and colors and how they interact with the overall design of the house.

Aluminum siding comes in a variety of styles and colors designed to mimic other materials or create a modern, clean look. The ability to customize the appearance allows homeowners to achieve a specific aesthetic without the higher cost and maintenance of traditional materials like wood or brick. This versatility makes it a popular choice for both renovations and new constructions.

Color Options and Finishes

Aluminum siding manufacturers offer an extensive palette of colors, ranging from classic neutrals to bold and vibrant hues. These colors are achieved through a durable powder-coating process, providing excellent protection against fading and chipping. Popular choices include various shades of white, beige, gray, and brown, which tend to complement a wide range of architectural styles. However, bolder colors like deep blues, greens, and reds can also be incorporated to create a striking visual impact, particularly on homes with modern or contemporary designs. Finishes also vary, offering options that mimic wood grain, stone textures, or a smooth, even surface. The choice of color and finish significantly impacts the overall appearance and should be carefully considered.

Aluminum Siding and Architectural Styles

The adaptability of aluminum siding makes it suitable for various architectural styles. For example, a classic colonial home might be complemented by aluminum siding in a muted, earth-toned color with a subtle texture that mimics wood clapboard. This creates a traditional look without the maintenance demands of real wood. A contemporary home, on the other hand, might benefit from sleek, smooth aluminum siding in a bold color like charcoal gray or deep blue, enhancing the modern lines and minimalist aesthetic. Ranch-style homes often look great with horizontal siding, while Victorian homes might use vertical siding or a combination of patterns to accentuate the architectural details. The choice of siding style and color should always be considered in relation to the existing architectural features and the desired overall effect.

Enhancing Curb Appeal with Aluminum Siding

To maximize curb appeal, careful consideration should be given to the interplay of color, style, and trim. Choosing colors that complement the roof, windows, and landscaping is crucial. For instance, a home with a dark gray roof might look stunning with light gray or beige aluminum siding, creating a balanced and visually appealing contrast. The use of contrasting trim colors, such as white or black, can add visual interest and highlight architectural details. Moreover, selecting a siding style that complements the home’s proportions and architectural features can significantly enhance its overall aesthetic. For example, vertical siding can make a home appear taller, while horizontal siding can emphasize its width. Paying attention to these details ensures that the aluminum siding not only protects the home but also enhances its beauty and value.

Hidden Costs

While the upfront cost of aluminum siding is a significant factor in your decision, several hidden expenses can significantly inflate the final bill. Understanding these potential costs beforehand is crucial for accurate budgeting and avoiding financial surprises during the installation process. Failing to account for these hidden costs can lead to project delays, budget overruns, and ultimately, homeowner dissatisfaction.

Permitting and Inspection Fees

Securing the necessary permits from your local municipality is a non-negotiable step in any home improvement project, including aluminum siding installation. These permits ensure your project complies with building codes and safety regulations. Permit fees vary widely depending on location, the scope of the project, and the complexity of the design. For example, a large home requiring extensive siding replacement might incur significantly higher permit fees than a smaller project involving only a section of the house. Additionally, you should anticipate inspection fees, which are typically charged for each stage of the installation process, ensuring compliance with the approved plans. Always inquire about these fees early in the planning process to accurately incorporate them into your budget.

Demolition and Removal Costs

Before the new aluminum siding can be installed, the existing siding (if any) needs to be removed. This demolition process may involve additional costs beyond the initial siding quote. For instance, if the old siding is difficult to remove due to its age or condition, the labor costs can increase substantially. Moreover, disposal fees for the removed materials must be considered. These costs depend on your local waste disposal regulations and the volume of material removed. It’s advisable to obtain separate quotes for demolition and waste removal to avoid unexpected expenses during the project’s execution. Consider obtaining multiple quotes to compare pricing.

Unexpected Repairs and Damage

During the siding removal and installation process, unforeseen damage to underlying structures may be discovered. This could involve rotted wood, damaged sheathing, or insect infestation requiring repairs before the new siding can be safely installed. These repairs can significantly impact the overall project cost, sometimes exceeding the initial siding estimate. A thorough inspection of the existing siding and underlying structure before starting the project can help minimize such surprises. A pre-installation inspection can provide a clearer picture of potential issues and associated repair costs.

Accurate Cost Estimation

Accurately estimating the total cost of an aluminum siding project requires a comprehensive approach. Obtain detailed quotes from at least three reputable contractors. Ensure these quotes clearly outline all aspects of the project, including materials, labor, permits, demolition, and waste disposal. Don’t hesitate to ask clarifying questions about any ambiguities. Consider adding a contingency buffer of 10-15% to the total cost to account for unforeseen expenses. This buffer helps avoid financial stress if unexpected issues arise during the installation. Compare the quotes meticulously, ensuring they cover the same scope of work before making a decision.

Aluminum Siding Installation Checklist: Avoiding Unexpected Expenses

To minimize unexpected costs, use this checklist throughout the process:

- Obtain multiple detailed quotes from reputable contractors.

- Inquire about permit and inspection fees upfront.

- Get separate quotes for demolition and waste removal.

- Request a thorough pre-installation inspection to identify potential repairs.

- Include a contingency buffer (10-15%) in your budget.

- Review the contract carefully before signing, ensuring all aspects of the project are clearly defined.

- Maintain open communication with the contractor throughout the process.

Conclusion

Ultimately, securing affordable aluminum siding for your home involves careful planning and research. By considering the factors outlined in this guide—from material selection and sourcing to installation and long-term maintenance—you can confidently make choices that enhance your home’s aesthetic appeal and value while staying within your budget. Remember to prioritize quality, obtain multiple quotes, and thoroughly vet any contractor before committing to a project. Your investment in new siding will enhance your home’s beauty and curb appeal for years to come.